News - 07.12.2022

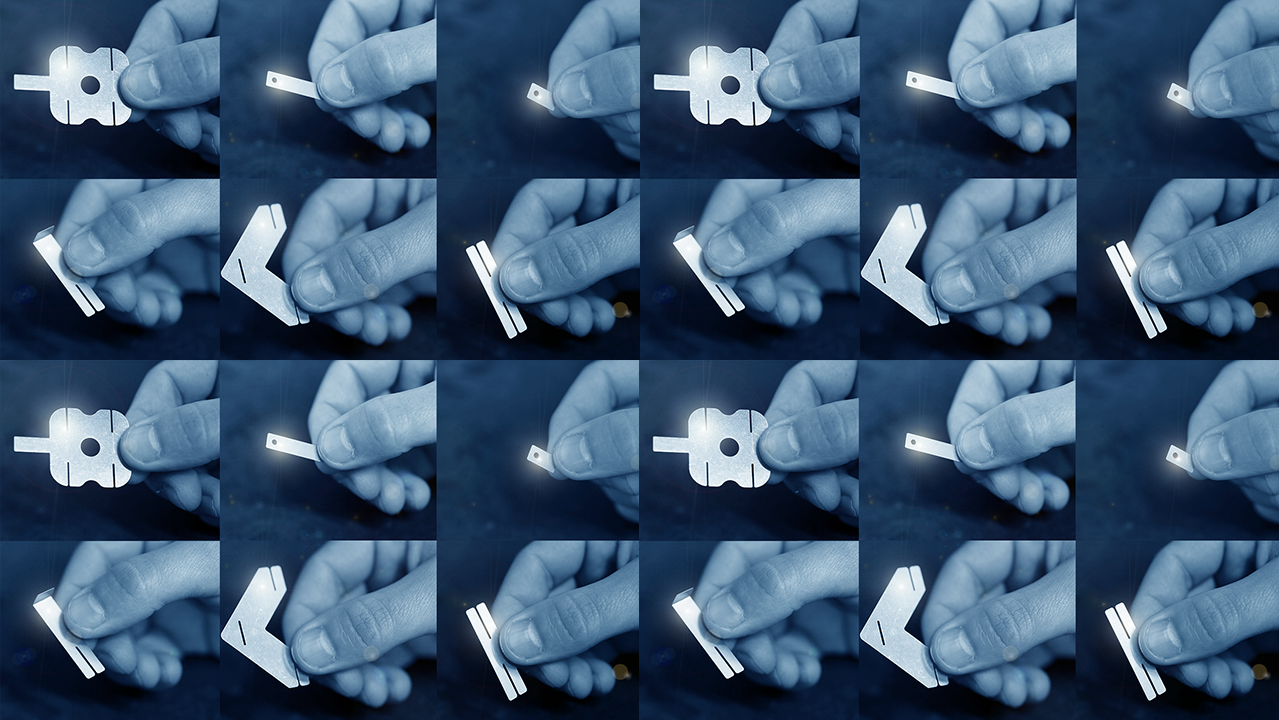

Thin Metal Processing & Specialist Laser Cutting

At Datum we process, machine, and sell ‘thin’ metal. Our stock ranges from 0.020mm up to our thickest material at 0.5mm.

Pete Anniss

Pete Anniss

During the past months we have learnt how ambiguous terms can be within our, and we’re sure many other industries. Thin metal processing would on the face of it appear clear, but we were wrong.

At Datum we process, machine, and sell ‘thin’ metal. Our stock ranges from 0.020mm up to our thickest material at 0.5mm.

It is the definition of ‘thin’ that adds ambiguity into the market.

Thin metal to many people in heavy industry or standard jobbing shops would be thickness of 5mm down to 1mm thick. These companies are experts in the areas in which they work but it is a different world to the one that we work in.

It is not unusual for Datum to be asked questions such as:

‘Can you process a sheet at 0.07mm thick with 16 areas machined down to 0.05mm?’

‘Can you laser cut a bespoke shape from 0.1mm, 0.12mm, 0.15mm and 0.20mm?’

There are many applications where multiple thickness substrate is required, such as:

- Battery connectors – for ease of spot-welding certain areas whilst maintaining the thicker substrate over the remaining foil to aid carrying more current

- Solder Stencils – to allow for different deposits of solder paste to be deposited onto printed circuit boards for more complicated designs

- Weight saving – many parts are weight critical and only certain parts of the substrate are required to be at a certain thickness

All these applications commonly use material thicknesses below 0.5mm.

Specialist laser cutting is also extremely ambiguous. Many firms can cut materials over 1mm thick to bespoke designs but small volume production and bespoke cutting of unique designs and parts below 0.5mm is less common.

There are constant requirements for this in the world of research and development as well as applications such as:

- Battery connectors – testing and small batch volumes of specific new designs that are constantly changing

- Shims that are specifically designed to fit in certain applications and require an extra level of precision on the thickness

- Architectural and display pieces

- Product / Components

- Prototypes

It is difficult to market capabilities for specific applications and difficult to advertise them generally, as they get pooled into the same group as the thicker materials above.

Working with R&D houses on exciting opportunities and challenging, new applications is great but spreading the word about the manufacturing methods and capabilities that we have outside of our existing market is tough.

We can offer the tightest thickness tolerances on the market from our stock stainless steel. We also hold a wide range of Nickel, and Nickel-plated steel for the battery connector market. Our machining capability allows us to cut pieces of material to any size and length as well as bespoke shapes or designs. In addition to this, we can machine features into the surfaces down to specific thicknesses in any designed pattern.

Laser cutting of any pattern or shape up to 700mm².

Machining down to give multiple thicknesses with a 5-micron tolerance on the finished thickness.

We developed the processes and machinery to be able to achieve the above for our current industry. We want to be challenged and believe that our capabilities can solve other industry challenges. Our innovation has allowed us to push the boundaries of what is possible for our current industry. Additional industries we are now serving have highlighted the above ambiguities when searching for ways to overcome certain challenges. With Datum’s support, experience, and expertise, we provide the solutions customers are looking for, making the once impossible, possible.