Solder Pallet Material

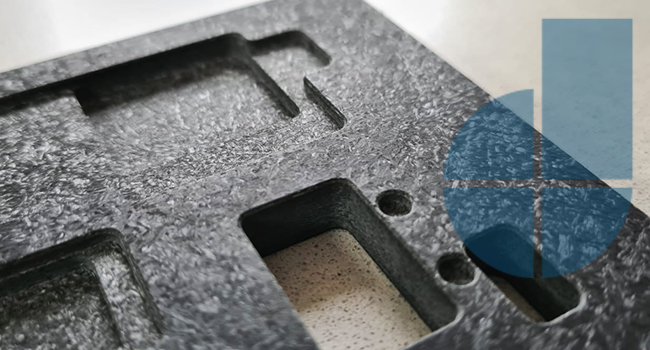

DCP – Datum’s wave solder pallet material is a premium ESD (Electro-Static Discharge) composite, pressed fibre, thermoset plastic which can be machined by manufacturers to create solder pallets or wave pallets used in wave solder machines as part of the PCB reflow process.

Solder pallets or wave pallets protect vital components during the reflow and wave solder process shielding the critical components from the high temperatures of the solder reflow machines. Our solder pallet material gives a reliable heat shield for heat sensitive and delicate components during the PCB component soldering process and with its ESD properties it protects critical components from electro-static charge.

DCP is made of high temperature glass fibre material and high-performance epoxy resin, allowing minimal fixture renewal, and maximizing productivity. Combining excellent machinability with a long service life our solder pallet material delivers direct cost benefits to both the pallet fabricator and the PCB assembler. The high-performance material enables faster cutting speeds and longer tool life. Its chemically resistant matrix ensures its solid performance through repeated reflow and has a demonstrated life of up to 10,000 solder cycles.

Advantages of using Datum DCP Solder Pallet Material

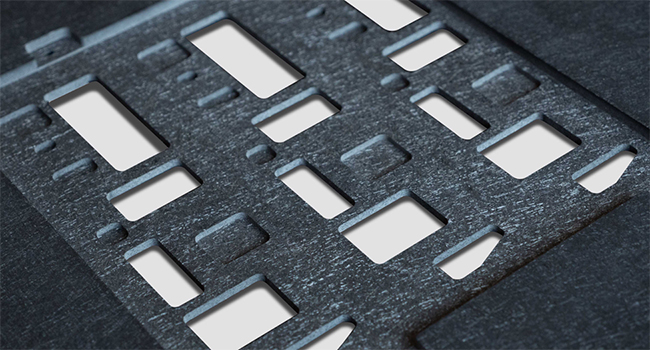

- Pressed fibre material – Enables excellent machinability and less dust resulting in longer tool life. Companies that use layered fibre material are more likely to experience chipping and pealing when machining or cleaning.

- Can be machined/milled down to a 1mm wall and floor thickness

- Small fibre composition prevents warping from expansion when going from hot to cold

- Fast cooling cycle

- Smooth finish causes the flux to roll off the surface, requiring less cleaning, less harsh cleaning agents and resulting in increased pallet life cycle

- Black and grey colour types – For CNC optical recognition

- Thicknesses from 2mm to 12mm held in stock at all times – Boards up to 100mm thick available on request

- Wide variety of sizes and thicknesses in stock – Bespoke sizes to order

Get in touch with our team on:

+44 (0) 1548 855 900 (UK & Europe)

+1 607 239 6274 (US)

+65 3157 0394 (Singapore)

Solder Pallet Material

Product Inquiry

Login

Please enter your name and email address to login.

Please contact us if you do not have an account

Customer Name

Order History

| Product | Unit Price | Quantity | Total |

|---|

Back to Order List

Customer Name

Order Details

| null | $0.00 |

|---|---|

| Quantity: 0 |

Total

| Taxes | $0.00 |

|---|---|

| Total | $0.00 |

Repeat Order

You can change the quantity and address on next page.

Repeat Order

Confirm Order

Please enter your name, email and confirm your shipping address to complete your order of:

Details

Details

Recommended machining parameters:

• Minimum wall and floor thickness: 1 mm (not recommended for large areas)

• Speed and feed rates: Spindle speed 7500 rpm, 8000 rpm max;

• Feed rate: 1200 mm/min (45 in/min) for a 6 mm (0.25 in) tool

• Cutter type: DCP needs hard metal tools such as Chrome-Vanadium. Typically use a 2 flute diamond coated tool.

• Coolant: Coolant is used to keep the dust contained but is not necessary for cutting. In the absence of coolant, a vacuum is required to remove the dust.

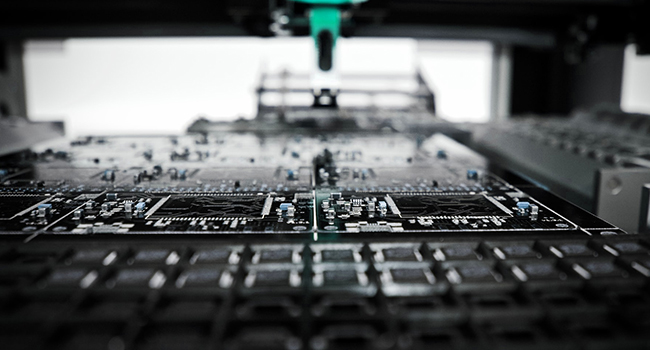

SMT (Surface Mount Technology) is the process of mounting electronic components on the surface of a PCB (Printed Circuit Board). Using a reflow oven, reflow soldering subjects solder paste to controlled heat to attach electronic components to the surface of the board.

"A study shows that even with the harshest of solder cycles – wave soldering – with three minutes of direct contact with 250°C solder and cooling to room temperature – concluded that:

• With 24-hour production, life cycle was projected to be 1.5 years

• With 12-hour production, life cycle was projected to be 2-2.5 years

• 2 years into production, no performance deficiencies were noted"

Additional recommendations included slower cooling between thermal cycles to preserve service life and projected 10,000 cycles for selective wave solder pallets due to their minimal contact with molten solder.

At Datum our solder pallet material has been developed for all procedures in the PCB tooling and assembly process including: solder paste printing, reflow soldering, wave soldering, SMT soldering and performs highly against electric arc and tracking making. Our solder pallet material is ideally suited for mechanical and electrical applications.

Benefits of Datum Solder Pallet Material:

• High strength

• Excellent machinability

• Durable - long life cycle

• Anti-static

• Resistant to reflow oven high temperatures

• Precision machining tolerance

• Chemical resistance

DCP - SOLDER PALLET MATERIAL |

BLACK |

GREY |

|---|---|---|

| Anti-static | ✓ | ✓ |

| Density (g/cm³) | 1.85 | 1.85 |

| Flexural Strength (Mpa) - perpendicular 3 point support | 360 | 360 |

| Water Absorption (%) | < 0.2% | < 0.2% |

| Coefficient of Linear Expansion (10-6/K) (30ºC - 200ºC) | 11 | 11 |

| Thermal Conductivity (W/mºK) | 0.25 | 0.25 |

| Minimum operating Temperature (ºC) | -60 | -60 |

| Maximum operating Temperature (ºC) 10-20 seconds | 300 | 300 |

| Continuous Operating Temperature (ºC) | 260 | 260 |

| Surface Resistance (ohms) | ≥1x104 to <1x1011 | ≥1x104 to <1x1011 |

| Specific Heat Capacity (J.kgK) | 930 | 930 |

| Barcol Hardness | 80 | 80 |

| Thickness Available (mm) Boards up to 100mm available on request | 3,4,5,6,8,10,12 | 3,4,5,6,8,10,12 |

| Thickness Tolerance | ±0.10mm | ±0.10mm |

| Flatness Tolerance • 300 x 300 Sheet • 600 x 400 sheet • 1220 x 1220 sheet • 1220 x 2440 sheet |

BLACK ±0.20mm ±0.68mm ±0.86mm ±1.36mm |

GREY ±0.20mm ±0.68mm ±0.86mm ±1.36mm |

| Parallelism | ±0.10mm | ±0.10mm |

Resources

Resources

Visit Datum’s Support Library for a complete list of resources.

VIEW ALL RESOURCESDatum Carrier Plate (DCP)- Data Sheet

View Details

Solder Pallet Material Comparison

View Details