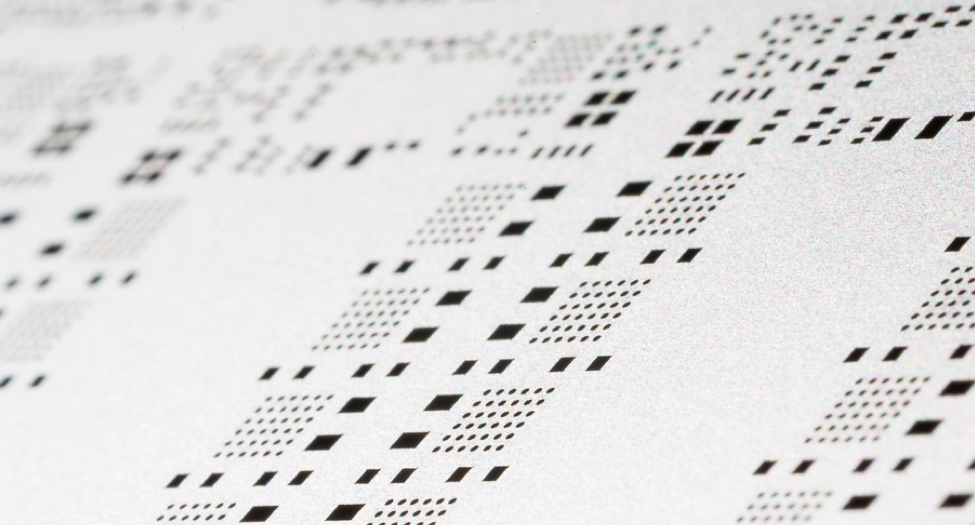

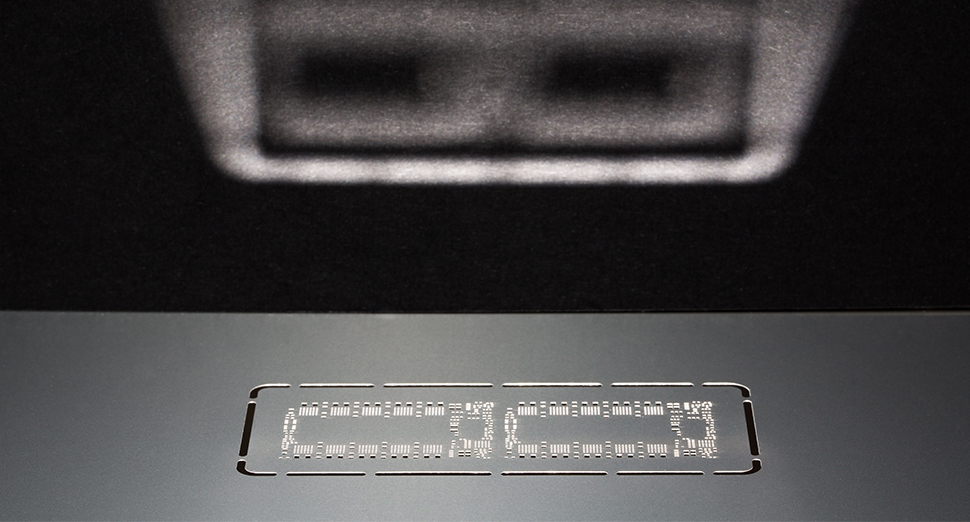

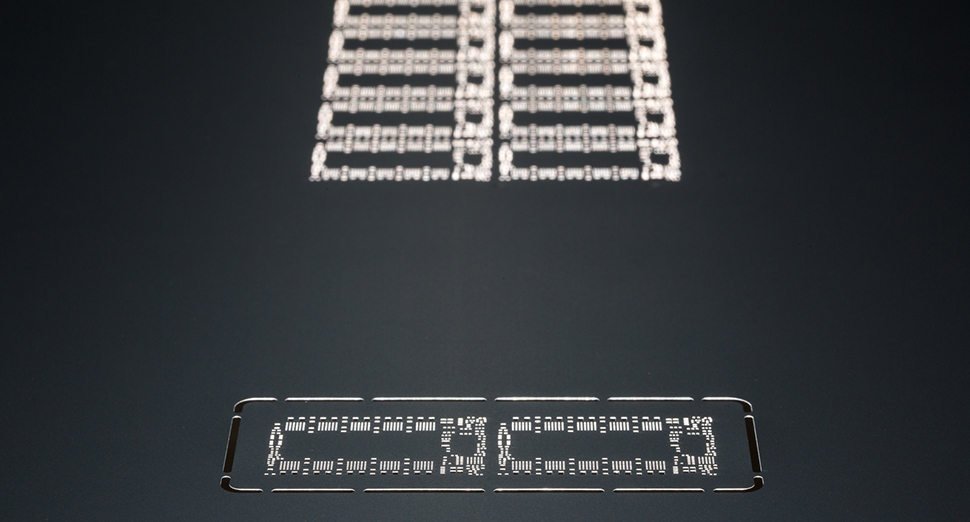

Datum is the market leader in SMT stencil foils because we revolutionized the technology within them. By studying the root causes of solder paste printing issues associated with foil materials, we developed HD. In 1996, this was the world’s first stress-relieved steel alloy specifically targeted to the laser-cut SMT stencil market. Then we developed PhD. Datum PhD’s innovative characteristics are its homogenous and recrystallized grain structure, which promotes cut – and therefore print – quality.

Datum PhD improved the quality of laser cut stencils and their resulting print performance in factories around the world. Since introducing this specialized SMT alloy, we have continued to improve stencil price and performance, introducing six new specialty SMT foil materials and a variety of frame and mounting technologies to the electronics assembly industry.