DATUM

DATUM

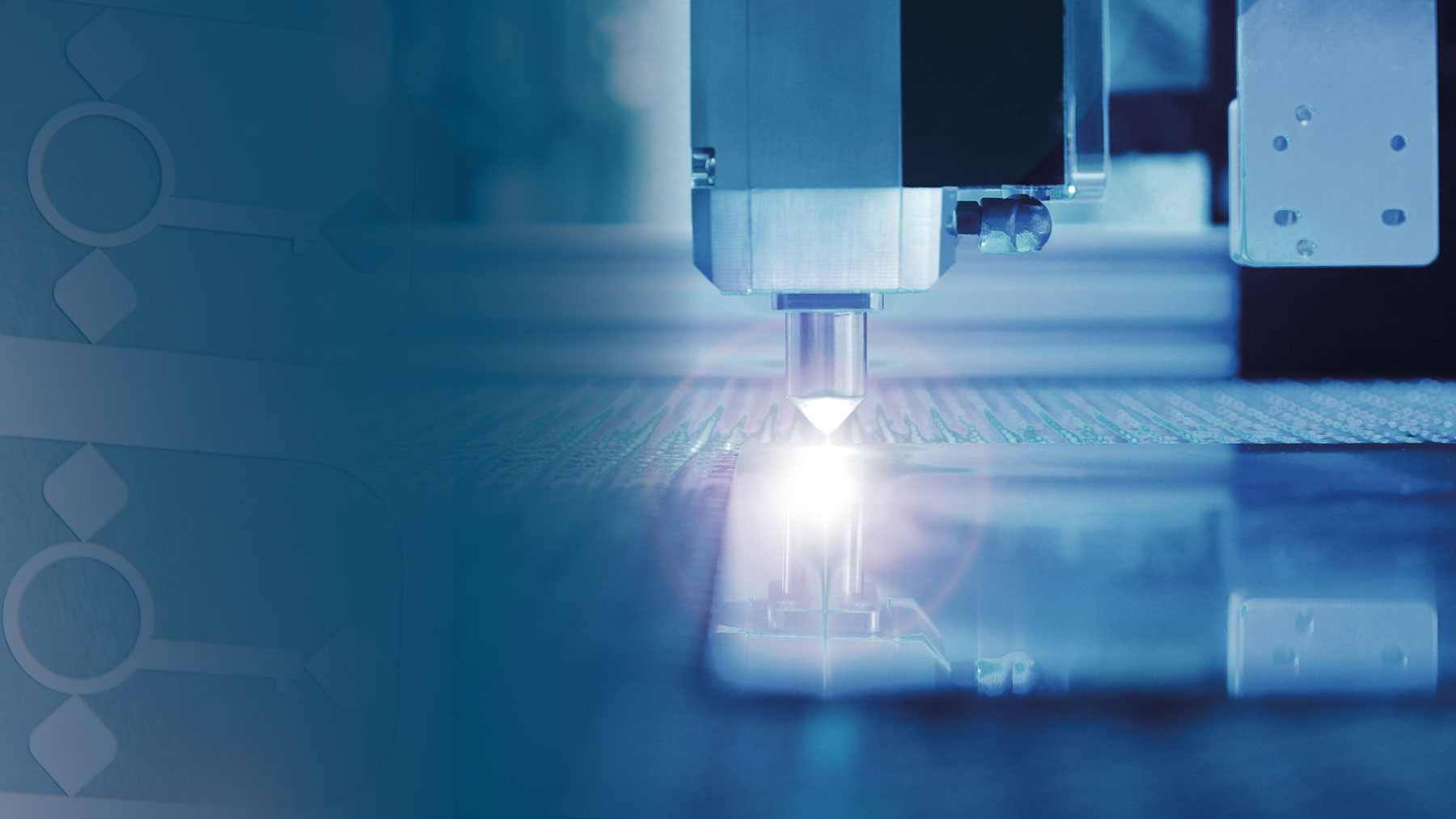

Datum Alloys specialise in the supply, handling, cutting and machining of thin metal sheet and foil to tight tolerances. Our bespoke coil to part laser and precision CNC milling machines produce laser cut and milled parts to order. From design to part, prototypes to production, we produce the highest quality, precision cut metal parts to your specifications.

Products

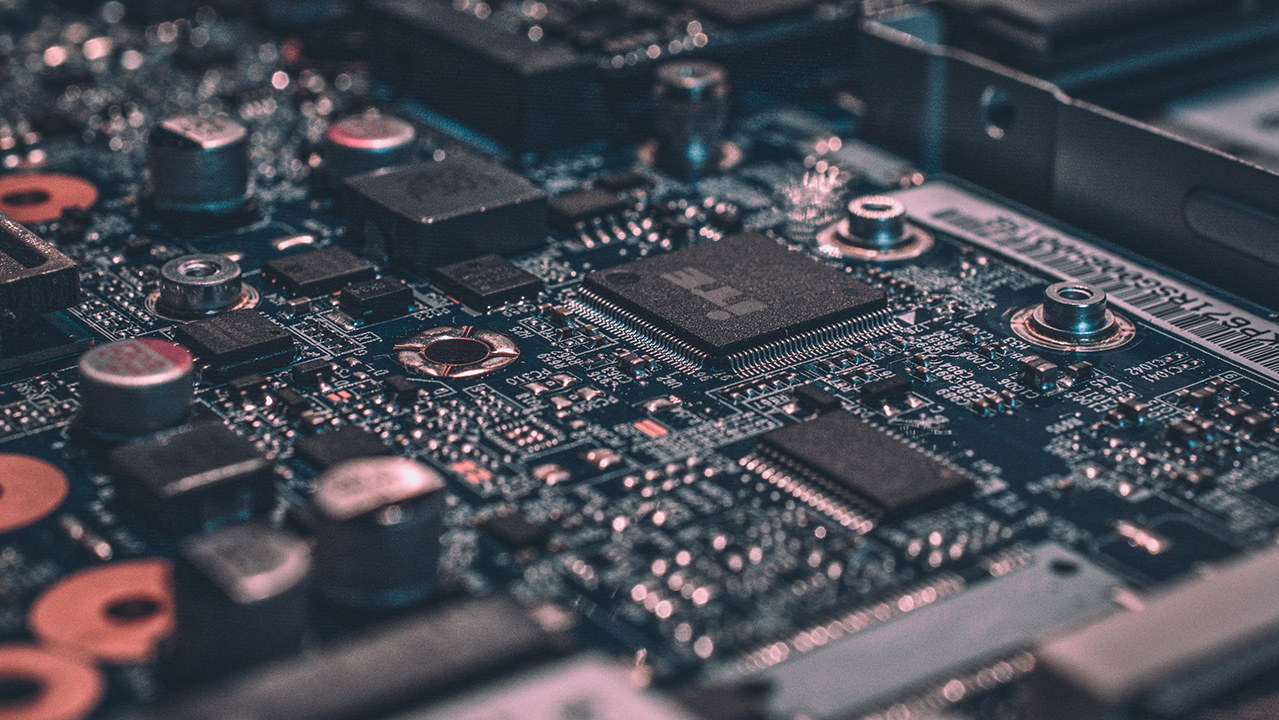

Our customers demand tools that work and materials that perform. Datum provides the tooling, materials and know-how necessary for technological advancement. We enable companies to build smaller, more complex devices and products.

At Datum, we are experienced problem solvers who thrive on complexity and the seemingly impossible. Three principles drive all that we do: listen, develop and deliver. We listen because all that matters is what our customers need. Understanding is crucial to success, and it defines our design process. We add value because we take the time to understand our customers’ and their desired outcomes.

We are not just selling a product, we are selling a service. We work with our customers to continuously develop and innovate, refusing to compromise.

We deliver products that outperform. Products that improve performance and raise the bar. This only comes from a team that has a clear understanding of who our customers are, and what winning means for them. We have a culture of innovating and doing. With locations in the UK, the US and Singapore, we service our customers worldwide.

AREAS OF EXPERTISE

AREAS OF EXPERTISE

Leaders in Innovation

01

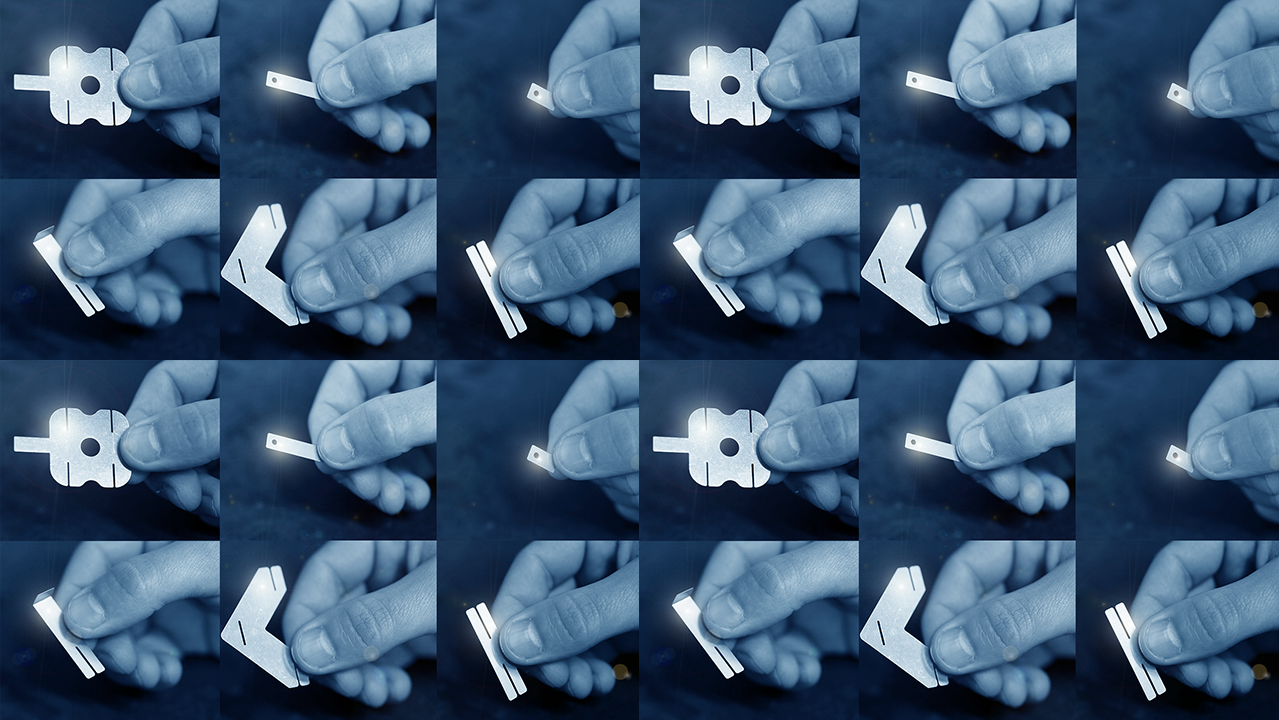

Foil Milling and Stencil Stepping

02

Laser Cutting

03

Datum Tension

04

Datum FG2

05

Datum PhD

OUR APPROACH

OUR APPROACH

Datum Initiatives

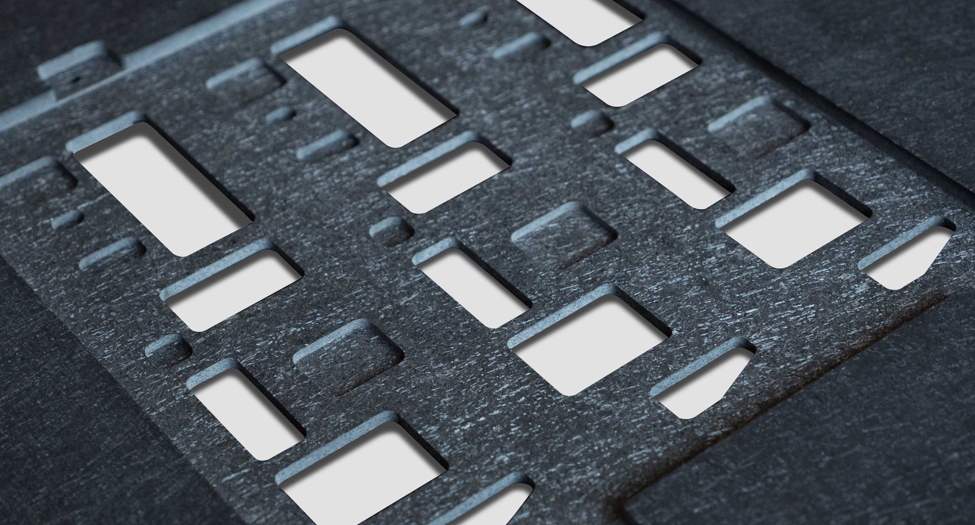

Advanced stainless steel foils for niche applications. Our foils are available from 0.020 mm thick and up to 700mm wide. We control every aspect of the foil – thickness, flatness, surface, grain size and structure and residual stresses. This results in foils that produce parts that last longer, perform better and look beautiful.

3D micro tools. We machine our foils and produce 3D parts, moulds, step, cavity and 3D stencils. These tools and components take our customers products beyond what is possible today with conventional processes such as etching, electro-forming, precision machining or laser profiling. With fewer limitations on feature size, tolerances and more material flexibility, where could we take you?

Learn More

NEWS & VIEWS

NEWS & VIEWS

Datum continues to be the leader of technology innovation. We stay focused on delivering unique solutions to keep our customers at the cutting-edge of technology.

View all News NEW DEVELOPMENTS

NEW DEVELOPMENTS

Datum is focused on delivering unique and innovative solutions to keep our customers at the cutting-edge of technology.