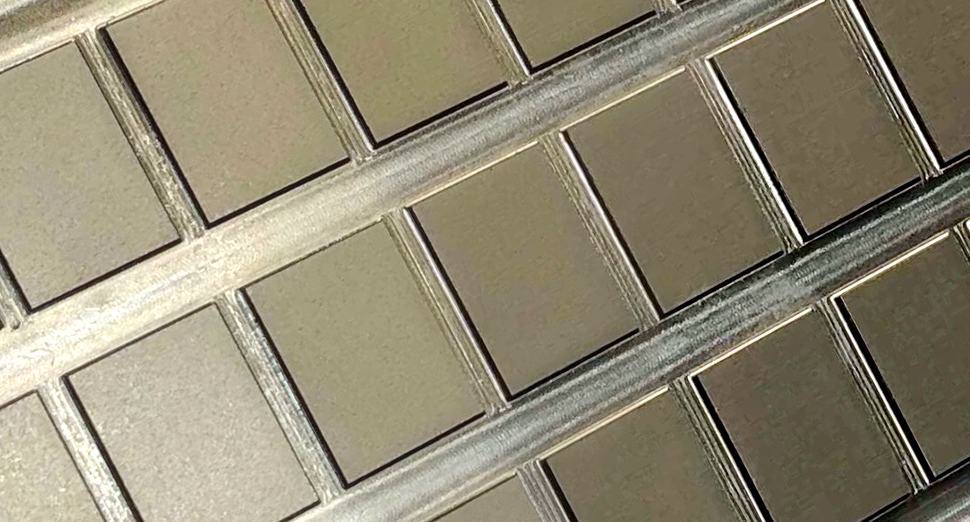

SMT Stepped Stencil

SMT Stepped stencils provide practical, workable solutions in a number of different applications:

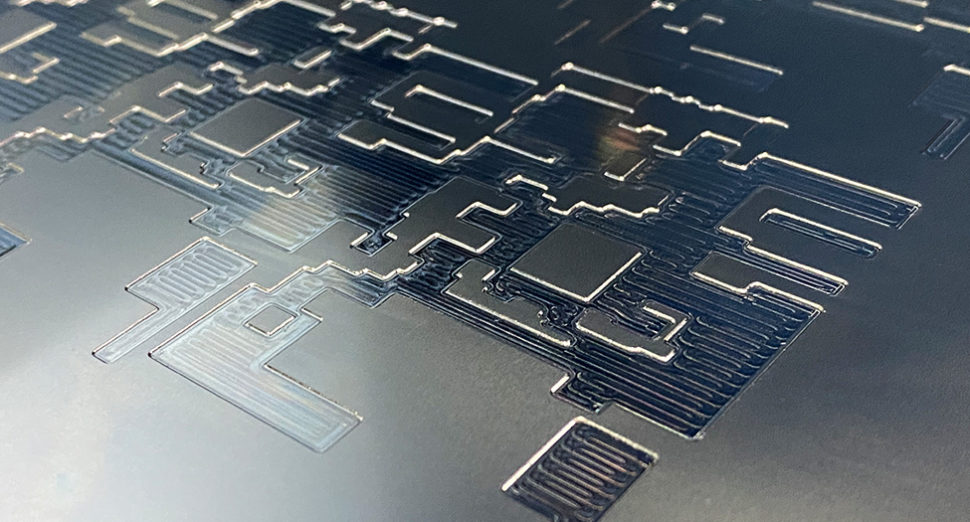

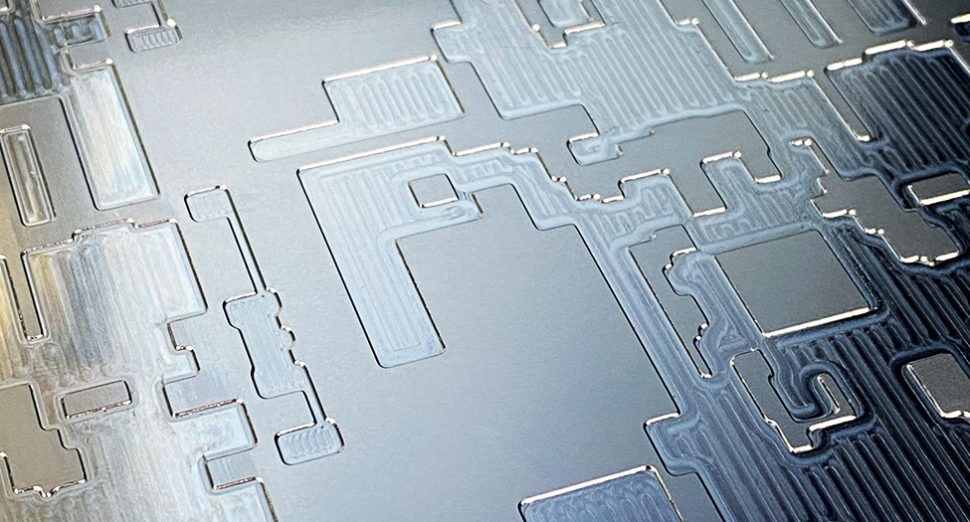

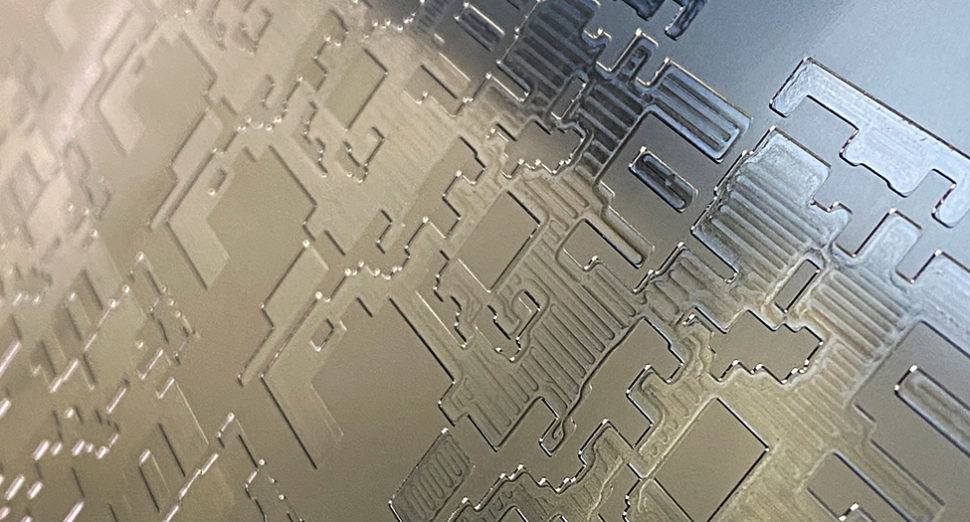

- Multilevel SMT stepped stencils vary the foil thickness locally to improve paste release on fine features or increase volumes on large or through-hole prints

- 3-D cavity stencils have topographies on the contact side to fit down into PCB cavities

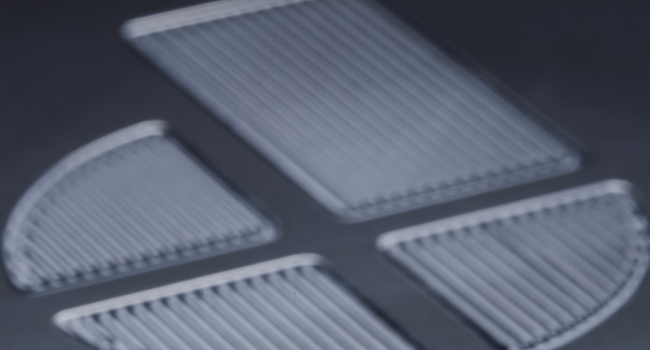

- BGA ball drop stencils often have “standoffs” built into the contact side to prevent sticky flux buildup on the stencil or in the apertures.

- Semiconductor ball drop stencils are similar to BGA ball drop stencils, but far more precise due to their small scale

SMT Stepped stencils can be created by a variety of manufacturing processes. Chemical milling (Chemical Etching), Laser Welding (Step up only) & Micromachining.

Datum produce multi-level, micro-machined step stencils in one continuous operation creating stepped stencils without distortion or burrs. Micro-Milling is the most flexible stepping method, able to create unlimited shapes, patterns, wall profiles and cavities.

All Datum materials are compatible with micro milling; for walls as thin as 20 µm, Datum Tension is suggested.

SMT Stepped Stencil

Product Inquiry

Login

Please enter your name and email address to login.

Please contact us if you do not have an account

Customer Name

Order History

| Product | Unit Price | Quantity | Total |

|---|

Back to Order List

Customer Name

Order Details

| null | $0.00 |

|---|---|

| Quantity: 0 |

Total

| Taxes | $0.00 |

|---|---|

| Total | $0.00 |

Repeat Order

You can change the quantity and address on next page.

Repeat Order

Confirm Order

Please enter your name, email and confirm your shipping address to complete your order of:

Details

Details

Welding locally changes the thickness of the foil by cutting identical slugs from the base stencil foil and the same material of a different thickness. The replacement piece is then welded into place in the base stencil before laser cutting. All Datum materials are compatible with laser welding processes.

Micromachining, or micromilling, uses a very precise CNC positioning system with very small, hard cutting tools to remove steel without distortion or burrs. It is the most flexible stepping method, able to create unlimited shapes, patterns, wall profiles and cavities. It is the most economical method of creating stencils with -multiple steps, or stencils that need contact side relief for board snuggers or labels. All Datum materials are compatible with micromilling; for walls as thin as 20 µm, Datum Tension is suggested.

Resources

Resources

Visit Datum’s Support Library for a complete list of resources.

VIEW ALL RESOURCESStencil Stepping Datasheet US

View Details

Stencil Stepping Datasheet UK

View Details