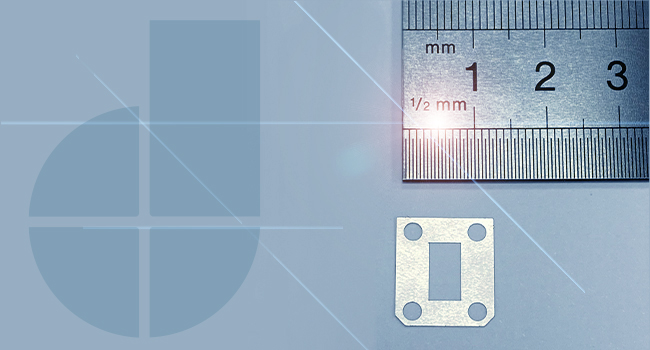

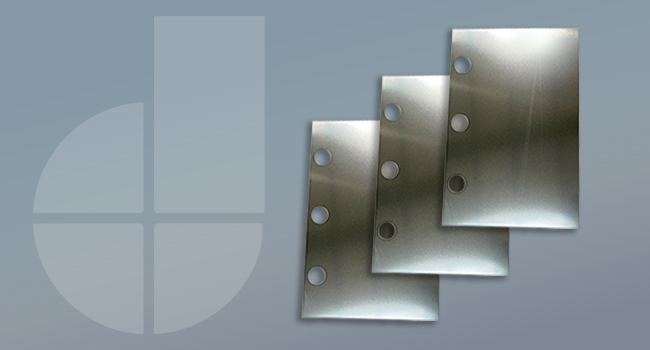

Steel Shims

Stainless Steel Shims

Datum manufacture laser cut, high-precision steel shims from coil or sheet. Our custom, precision metal shims are made to short lead times and tight tolerances. We are ISO 9001:2015 certified ensuring accuracy and reliability on every order. Our products are trusted by engineers in medical, aerospace & tech industries globally.

Key features include:

- Highly efficient process

- Components up to 690mm²

- All common grades and tempers of stainless steel between 0.05mm and 0.50mm

- Highly accurate and repeatable

- 3D features

- Fast turnaround

Get in touch with our team for your precision laser cutting requirements on:

+44 (0) 1548 855 900 (UK & Europe)

+1 607 239 6274 (US)

+65 3157 0394 (Singapore)

Steel Shims

Product Inquiry

Login

Please enter your name and email address to login.

Please contact us if you do not have an account

Customer Name

Order History

| Product | Unit Price | Quantity | Total |

|---|

Back to Order List

Customer Name

Order Details

| null | $0.00 |

|---|---|

| Quantity: 0 |

Total

| Taxes | $0.00 |

|---|---|

| Total | $0.00 |

Repeat Order

You can change the quantity and address on next page.

Repeat Order

Confirm Order

Please enter your name, email and confirm your shipping address to complete your order of:

Details

Details

We specialise in prototype laser cutting to bespoke shapes and sizes to drawing, as well as strips of shim. Our precision manufacturing process uses high quality materials and production methods to produce superior performance packers, shims, gaskets, washers and spacers to customer specification. Using the latest equipment our precision technicians produce stainless-steel shims from 0.05mm to 0.5mm thick. We can also micro laser cut other alloys such as Aluminium, Alloy 42, Nickel coated steel and Copper to suit your requirements.

Our production facilities in the UK and US provide precise, efficient manufacturing and fabrication of your finished part, ensuring consistency with every order.

Gaps can often occur between different components in the manufacturing process. When components are able to move around they can cause friction damage to your product or device. Steel shims are thin pieces of material commonly used to fill gaps between objects to remove excess play or to make a surface level. Shim washers can improve alignment between components without having to make alterations to your mechanical device – offering a cost effective and non invasive solution.

Steel shims have very low distortion and breakage when subject to high load. As such they are able to absorb impact and protect against damage in tight spaces.

Our shims are used in highly precise apparatus requiring specific spacing requirements and can be manufactured from 0.05mm to 0.50mm thick. At Datum we can supply pre-cut shims to your exact specification, or provide stainless steel on foil or sheet. Our 301 & 304 stainless-steel shim stock rolls are easy to form and can be laser cut or milled to tight tolerances. We can create bespoke steel shims for many applications including:

- Precision adjustments and alignments in machinery

- Tool and die set up

- Machine repair

- Machine maintenance

- Prototype work

Our process produces scratch free, precision stainless steel shims to our customers precise specification. Our UK and US shim manufacturing facilities specialise in both high precision small batch prototyping and large scale manufacture. In addition we produce components with 3D features by micromachining; a second operation carried out after laser cutting that produces microscale features on your components. These processes together give you the precision and repeatability of laser cutting and micromachining with the flexibility of etching.

At Datum we use high grade metals for our laser cut parts including:

301 stainless steel (Datum Tension/Fine Grain)

Extra hard stainless

0.05mm to 0.2mm thick

304 stainless steel (Datum PhD)

Hard rolled stainless

0.02mm to 0.50mm thick

Nickel 200/201 Nickel coated steel, Nickel coated Copper

Our laser cutting process can produce shims to the most intricate of sizes fast and efficiently without compromising on quality.

Parameter |

Value |

|---|---|

| Max cutting area (Single sheet) | 610mm x 610mm |

| Max cutting area (From Coil) | 700mm x 700mm |

| Sheet width tolerance, full width | ±0.50mm |

| Sheet width tolerance, Laser Cut (with offcuts) | ±0.03mm per 200mm |

| Sheet length tolerance using Guillotine | ±0.25mm |

| Sheet Squareness tolerance using Guillotine | ±0.30mm |

| Sheet length tolerance Laser Cut (with Tabs) | ±0.03mm per 200mm |

| Max material thickness | 0.50mm |

| Min material thickness | 0.05mm |

| X and Y Axis Positional tolerance | ±0.05mm |

| X and Y Axis Combined Positional tolerance | ±0.07mm |

| X and Y overall Feature dimensional tolerance | ±0.02mm |

| Parallelism |

±0.1 Deg |

| Perpendicularity | ±0.2 Deg |

| Material Types | Metal |

| Laser beam diameter | <0.08mm |

Metal shim manufacturers providing shim cutting services and shim foil from facilities in the UK and US- exporting globally.