News - 08.28.2018

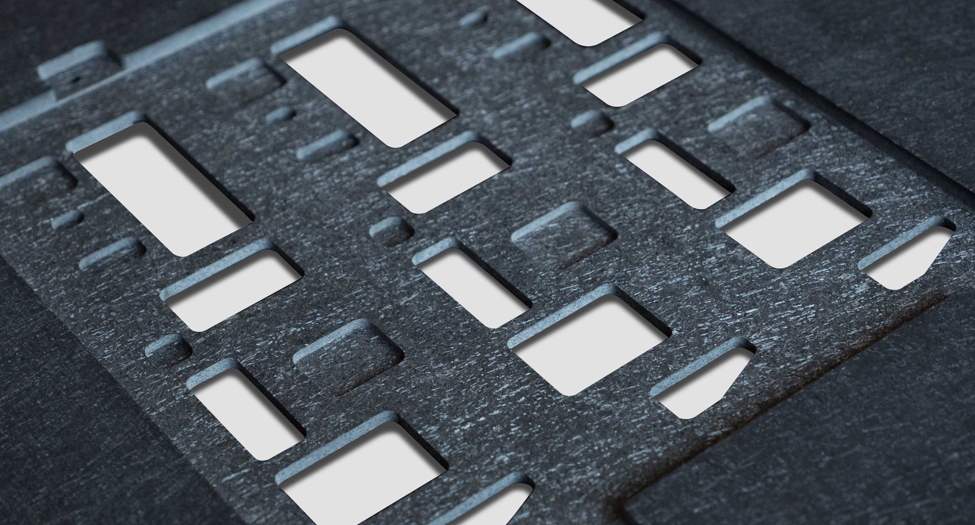

Customer Case Study on DCP Service Life

Background

Datum Carrier Plate (DCP) is a composite-thermoset plastic offered in Electro Static Discharge (ESD) and non-ESD versions with high chemical-resistance, excellent machinability and long service life.

The product uses a high performance glass-filler in a chemically resistant matrix.

The following information on how ESD-safe DCP performs in a production environment is based on feedback from one of our original DCP customers.

Customer

Róbert Polgár

MSc.Mechanical Engineer

Lasertec International Kft

Situation

The most critical factor affecting DCP service life based on life cycles is the time and temperature at which the heated solder is in contact with the material.

Figure 1 – Wave solder thermal profile

Figure 2 – Reflow solder thermal profile

There are 3 ways in which DCP is used, and each soldering process has different contact characteristics:

- Wave Soldering – Direct contact with molten solder has the highest “shock impact” for the pallet material

- Selective Soldering – No direct contact with the molten solder helps to extend the life cycle

- Reflow Soldering – High temperature and long exposure, but no contact with molten solder extends the service life further

Results

Wave soldering has the harshest thermal cycle, as seen in Figure 1. Some profiles have a longer time at lower temperatures while others have shorter times but at higher temperatures, but they all follow the same general parameters. The same is true for reflow soldering. A typical reflow solder profile is seen in Figure 2.

No two production lines are the same so the results will vary from one line to another but the following are the average results for the black (ESD-safe) DCP material:

Wave soldering – 3 minutes maximum time of contact at a maximum temperature of 250 degrees Celsius:

- 24 hours production – about 1.5 years life time

- 12 hours production – 2-2.5 years life time.

Selective wave soldering – life time is up to 10 years because the solder material doesn’t have direct contact with the pallet.

The lifetime will also depend on the cooling process. If the pallet is allowed to cool down slowly, the life cycle will be longer, presumably due to the minimization of thermal shock.

Conclusion

Datum DCP performs well across typical heating and cooling cycles and no issues have been reported after more than 2 years of production usage.