Case, Developments, News - 04.23.2024

Innovating Carbon Fibre Recycling Technology

Datum Alloys, a leading provider of bespoke laser cutting solutions, celebrates its collaboration with Lineat Composites, a pioneering start-up based in Bristol.

Ross Howard

Ross Howard

Datum Alloys, a leading provider of bespoke laser cutting solutions, celebrates its collaboration with Lineat Composites, a pioneering start-up based in Bristol who are developing carbon fibre recycling technology using their parallel plate fibre alignment technology.

At Datum, we are proud to supply precision laser cut parts and support Lineat in their efforts to revolutionise the carbon fibre industry by developing innovative solutions for processing and recycling carbon fibre materials.

Carbon fibre, renowned for its strength and lightweight properties, has long been a staple in various industries, from aerospace to sports equipment. However, its production and disposal present significant environmental challenges.

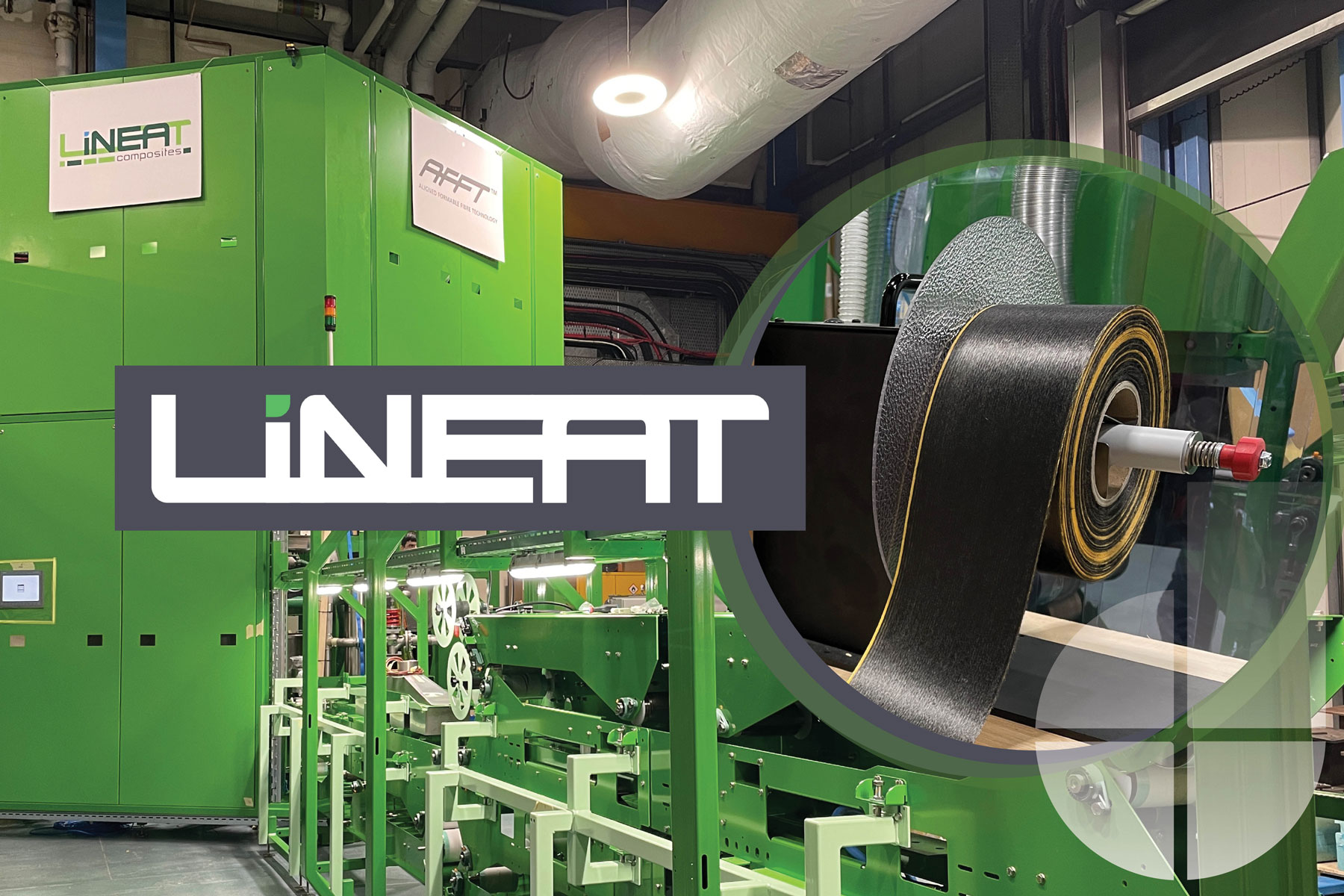

Lineat Composites is a start-up based in Bristol who are creating the world’s strongest recycled material by re-processing chopped carbon fibre waste into new aligned carbon fibre tapes. Lightweight carbon fibre materials have a heavy impact; they are expensive (>40x the price per kg than steel) and polluting (20x CO2e emissions per kg than steel). Carbon fibre cannot be remelted like metals; thus, offcuts and end-of-life material typically get shredded or milled and put into landfill.

Lineat Composites recognised this issue and embarked on a mission to transform carbon fibre waste into reusable materials, thereby reducing both cost and environmental impact.

The Lineat process is a high-tech adaption of the traditional papermaking process. Recycled chopped carbon fibre waste, consisting of random fibre bundles, is first dispersed in water in fibre filaments. These are then carefully sprayed between parallel plates to create continuous strands of highly aligned fibres all situated next to each other. By re-aligning the short fibres, the new recycled material mimics the original continuous fibre and retains its high strength properties. This way, single-use carbon fibre becomes a multi-use material. Lineat have already shown this can be used to close the loop for carbon fibre in the sports industry, having creating world’s first recycled tennis racket with W labs using fibres recovered from broken tennis rackets.

Dr. Lourens Blok, the Chief Technology Officer at Lineat Composites, explains, “Our vision is to make carbon fibre a multi-use commodity material and significantly increase the recycling rate from the current <10% to over 50%.”

Datum Alloys plays a crucial role in supporting Lineat Composites’ vision by providing bespoke alignment plates with ultra-fine tolerance, essential for aligning chopped carbon fibre with precision. Dr. Blok acknowledges the importance of Datum Alloys’ contribution, stating, “One of the benefits of Datum Alloys is the extreme flatness of the supplied laser-cut plates. This has been a game changer for us to upscale our process while keeping to tight tolerances to ensure we hit our required fibre alignment levels.”

Lineat Composites recently completed its first commercial pilot line in Bristol and looks ahead to scaling up production to machines capable of processing over 100 tonnes of fibre per year. This ambitious endeavour involves aligning a staggering 977 billion chopped fibres every day, underscoring the critical need for ultra-flat and high-tolerance plates supplied by Datum Alloys.

“We are immensely proud to collaborate with Lineat Composites in their mission to revolutionise the carbon fibre industry,” says Ross Howard, Sales & Marketing Director of Datum Alloys. “Their innovative approach to recycling carbon fibre aligns perfectly with our commitment to supporting cutting-edge technologies. We look forward to continuing our partnership with Lineat Composites and contributing to their success in the years to come.”

In a world where sustainability and innovation are paramount, the collaboration between Datum Alloys and Lineat Composites exemplifies the power of partnership in driving positive change and shaping the future of materials engineering.