News - 07.16.2019

The Wide Range of Datum Technology

Datum's latest technology updates

Ian John

Ian John

Datum is always working to develop new innovations and work with new technology to create new solutions for the problems of today and tomorrow. Our range of products is very niche and tailored quite specifically to PCB manufacturing. We’ve cornered this market with a narrow and highly focused range. Though we provide a small number of products, those products make up a large proportion of raw material that goes into the electronics industry. So what’s next for Datum?

First, we are working to increase manufacturing to broaden our range and use, and to develop our expertise in wider markets.

For the past two years, we’ve been evolving from just selling raw materials to selling a finished product. It’s not about making it easier for our customer; it’s about changing what we do.

As a small organisation, we need to consider new developments carefully. The market in which we operate, despite being a quite advanced market, gets nervous about change and is slow to adopt new products. So, although we are constantly looking for better materials, this can be a double edged sword. Any changes that we make need to be well researched, thought out and obviously superior.

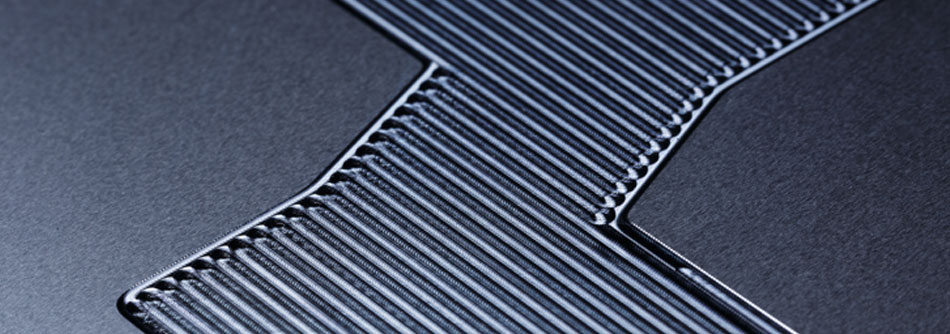

We started, effectively, as a material supplier with a bit of assembly. We were selling steel and other raw material. Then we advanced to mount foils onto frames, and then started milling. Laser cutting is the latest addition to our offerings. Now, we are building our expertise in manufacturing. Some of the products that we currently manufacture, like our frames and milled foils, are already the best and made using the industry’s best available materials.

Our most prominent opportunity for innovation and improvement is our new laser, which is currently taking up most of our resources. Within the last week or so, we have made huge advances in cut quality. Cut quality is paramount to a high-caliber material. When you cut steel with a laser, the entry side has a smooth cut while the back side has a burr. When we started, this burr was around 150 microns. We made improvements to bring it down to 80 microns. In the past few days, we’ve brought that number down again, to 5 microns.

This laser has allowed us to program and cut samples into stainless steel sheets. The past two years of development work have finally come to fruition. Now we can approach any company who needs to cut pieces out of thin materials and can make them samples with complete confidence that we’ll meet, and exceed, their standards.

It’s another example of Datum accomplishing something that most in the industry originally thought couldn’t be done.