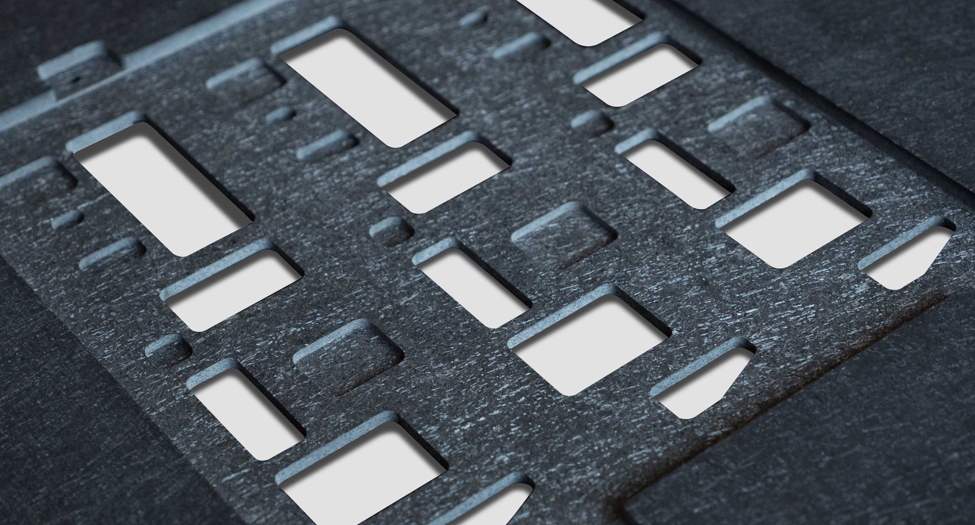

A 2016 user study showed that even with the harshest of solder cycles – wave soldering – with three minutes of direct contact with 250°C solder and cooling to room temperature – concluded that:

- With 24 hour production, life cycle was projected to be 1.5 years

- With 12 hour production, life cycle was projected to be 2-2.5 years

- 2 years into production, no performance deficiencies were noted

Additional recommendations included slower cooling between thermal cycles to preserve service life and projected 10,000 cycles for selective wave solder pallets due to their minimal contact with molten solder. Read the full report here.