CNC Machining

At Datum we provide CNC micromachining services, producing micro milled sheet metal and foil.

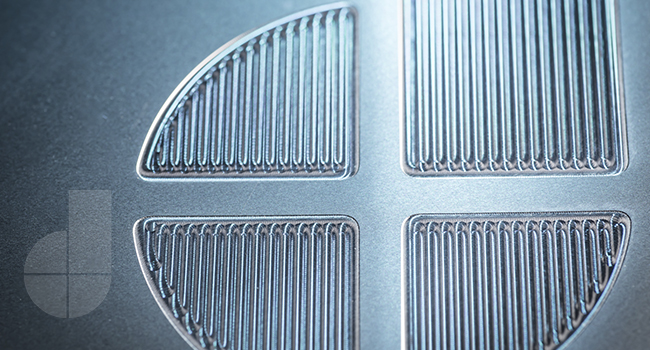

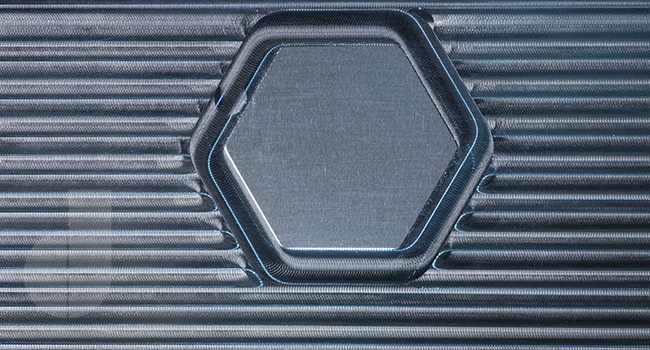

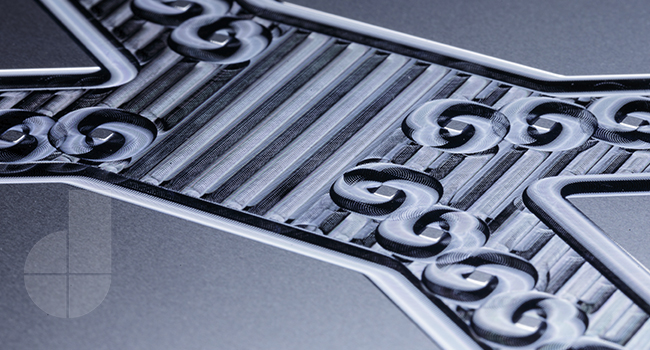

Our precision, CNC milling machine produces shapes, contours, and pockets in the surface of thin metal sheet and foil. This process is perfect for producing multi-level surface heights on foils used as stepped stencils for the application of solder paste to PCB’s used in the SMT market.

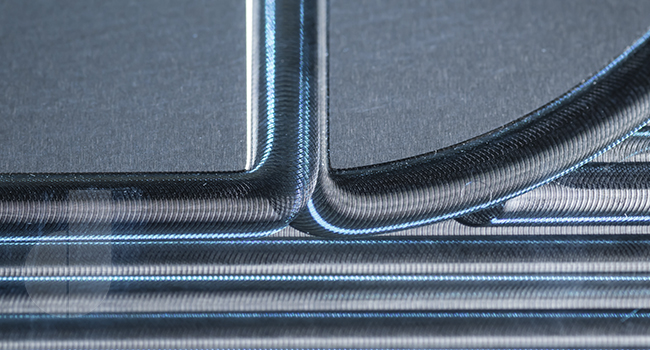

Datum supplies customised micro-profiled sheet and foil ready to be laser cut to stencils, offering significantly improved levels of positional accuracy, surface finish and transition control for small geometries. A stepped stencil enables the SMT manufacturer to apply varied thicknesses of solder paste to a PCB, suitable for different size components in one pass during the screen-printing process.

Machined stepped stencils are an efficient more precise alternative to welded or chemically etched stepped stencils. In a world where micro-components are becoming smaller, having the control over the thickness and dimensions of foil depths plays a critical role in the SMT process.

With micro-CNC milling capabilities, Datum’s small parts, CNC machining expertise enables us to produce high precision, small components to micron level tolerances. We also mill steps and pockets as part of our small parts CNC machining process, a second operation performed after laser cutting that produces microscale features on your components. These processes together give you the precision and repeatability of laser cutting and micromachining and the flexibility of etching.

Get in touch with our team for your CNC machined requirements on:

+44 (0) 1548 855 900 (UK & Europe)

+1 607 239 6274 (US)

+65 3157 0394 (Singapore)

CNC Machining

Product Inquiry

Login

Please enter your name and email address to login.

Please contact us if you do not have an account

Customer Name

Order History

| Product | Unit Price | Quantity | Total |

|---|

Back to Order List

Customer Name

Order Details

| null | $0.00 |

|---|---|

| Quantity: 0 |

Total

| Taxes | $0.00 |

|---|---|

| Total | $0.00 |

Repeat Order

Repeat Order

Confirm Order

Please enter your name and email address to finish your order of:

TODO: Need to collect the following info: NeedByDate*, Address.

Product Details

Product Details

Datum micro-profiling produces steps on the foil with the following benefits critical to the SMT process.

• Z- Axis dimensional accuracy within 5μm

• Complete edge control ensures a consistent angle and radius allowing apertures to be designed closer to steps and pockets.

• A more gradual transition in stepped areas can extend the life of the squeegee and stop paste build up within the transition.

• Surface finish approaching or the same as virgin cold roll PHD or Tension stencil materials. Guaranteed < 0.50 μm but typically < 0.30 μm.

These features reduce variability within the print process and help deliver certainty.

With facilities located in the UK and US—Datum has the ability to service our customers globally and across regional and market needs.

Parameter |

Value |

|---|---|

| Max material thickness | 2mm |

| Min material thickness | 0.05mm |

| Z Depth Tolerance | ± 0.005mm |

| X – Y Plane Circularity | 0.005mm |

| Surface finish | <0.25 Ra |

Parameter |

Value |

|---|---|

| Max material thickness | 2mm |

| Min material thickness | 0.05mm |

| Z Depth Tolerance | ± 0.005mm |

| X – Y Plane Circularity | 0.083mm |

| Surface finish | <0.20 Ra |